Deposition basic information

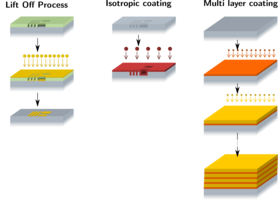

Deposition describes a variety of methods that are used in micro- and nanofabrication to produce thin films and coatings. The TDSU 1 runs different systems for directed as well as conformal deposition of metal, dielectric and Si-based layers.

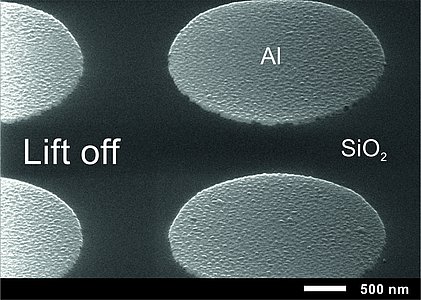

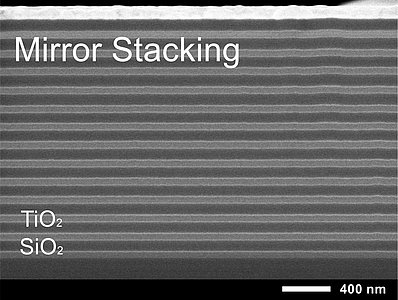

The evaporation and sputtering systems aim for directed deposition of metals and dielectrics. Depending on the tool they are designed to support micro structuring processes such as lift off, angle dependent or ion assisted deposition.

The plasma enhanced chemical vapour deposition (PECVD) is used to grow conformal Si-based active as well as isolation and passivation layers. It yields to relatively fast deposition rates while maintaining the film quality.

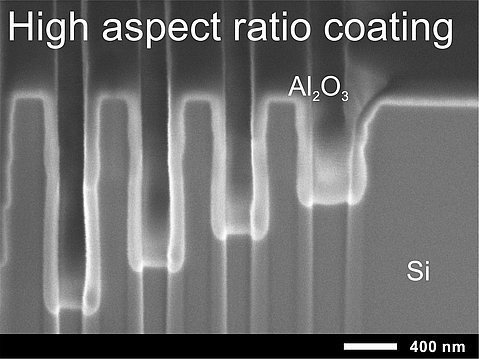

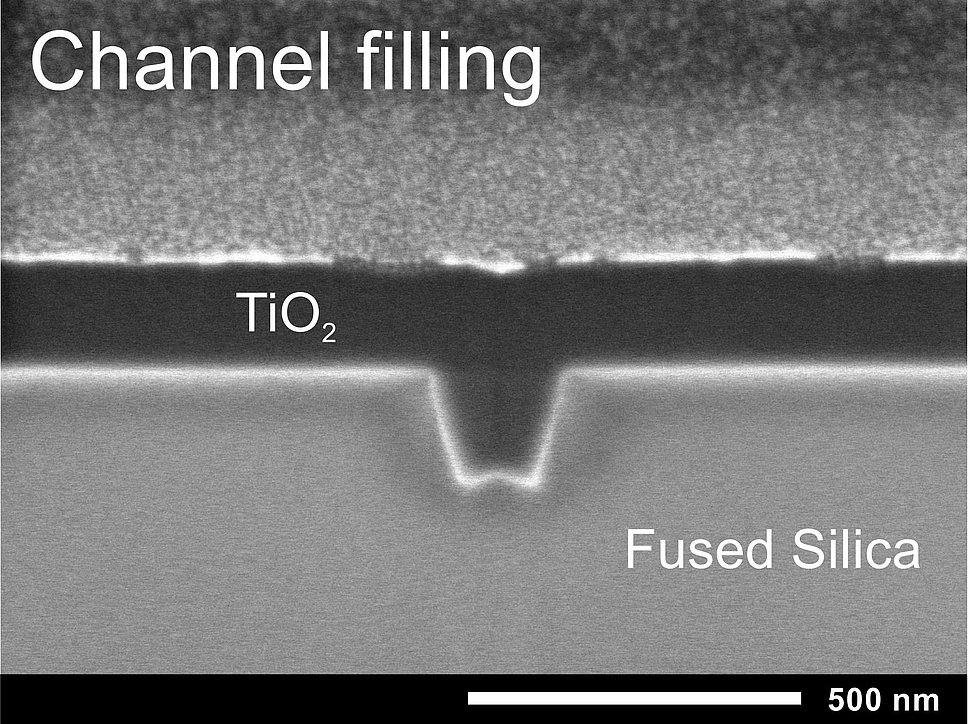

The atomic layer deposition (ALD) is the best choice for thin film high aspect ratio coatings. Sequential pulsing with precursors allows a self-limiting growth process which provides high quality thin film layers with precise control of the thickness at an atomic level.