A freezing Advancement

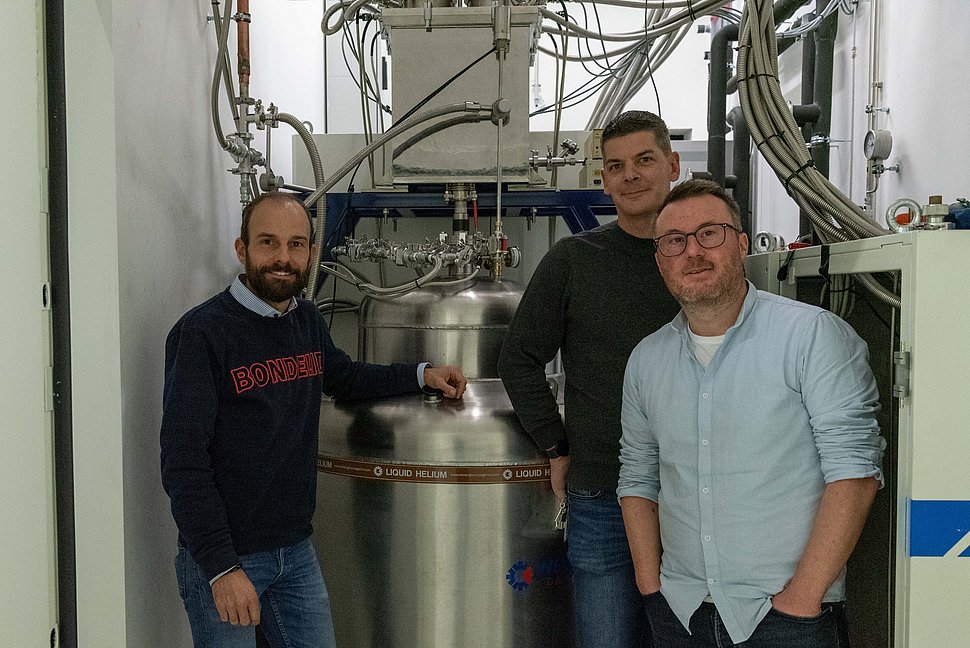

MPL has put its new helium liquefaction system into operation. It enables researchers to recover and reuse liquid helium sustainably and independently of the global market. Liquid helium is required to perform many experiments at temperatures close to absolute zero.

Tobias Utikal with Matthias Freudensprung, head of purchasing and Adrian Thoma, head of the building technology department in front of the new helium liquefaction system.

Tobias Utical and Fabien Greiner with the first 100 Liters of liquefied helium from the new system.

Helium is the second most common element in the universe. Paradoxically, it’s also incredibly rare here on earth. It is generated deep underground when elements such as uranium decay and then seeps upwards through the Earth’s crust. On its way it sometimes gets trapped in pockets of natural gas. If not, then the helium, being lightweight, can simply float out of our atmosphere and disappear into space. Only in a few countries, such as the United States, Quatar, Algeria or Russia, is Helium successfully extracted which in recent years has caused the price of helium to go up dramatically. Tobias Utikal, from the research group of MPL director Vahid Sandoghdar, remembers: „When our group got started in 2011, we paid 6 Euros per Liter of liquid helium. Now we pay 35 Euros.“ The group needs between 300 and 500 Liters every week as a coolant agent for experiments that run at close to absolute zero temperatures, where only helium can stay in a liquid form. So a decision was made to search for a cheaper and more sustainable alternative.

In 2012 the team bought a new system, that allowed them to recapture the liquid helium as it evaporates after use. However, they then needed to ship it to the next helium liquefaction plant, which the Friedrich-Alexander-Universität Erlangen-Nürnberg runs. This was, as Utikal puts it, a logistical nightmare, as helium is considered a hazardous substance and is thus, very difficult to transport. So the decision was made to look for a system that the Institute could implement itself. However, at that point in time, helium liquefaction systems only came in two sizes: Table-setups, which have a very small production capacity, in addition to being very loud and causing a lot vibrations, or huge systems typically run by large universities. Finally in 2019, the MPL group was able to find a brand new system on the market that had a production capacity just right for their needs. Additionally, this new system also runs almost fully automatically, thus not requiring trained personal to be hired to run it.

Implementing such a still very large machine was a mammoth logistical task. Now though, the system, in its particular size likely unique in Germany, is up and running. With it, the MPL now has a fully closed cycle of use for liquid helium in its experiments. Tobias Utikal is thrilled: „Once its properly set up, using it is not much more complicated than using a water dispenser! With it, we are much less reliant on the world market and the helium prizes, which don’t look to be coming down any time soon.“

Contact

Edda Fischer

Head of Communication and Marketing

Phone: +49 (0)9131 7133 805

MPLpresse@mpl.mpg.de