AutoRAPID project enters the home stretch: Successful trial installation of the integrated structure at the Max Planck Institute for the Science of Light in Erlangen.

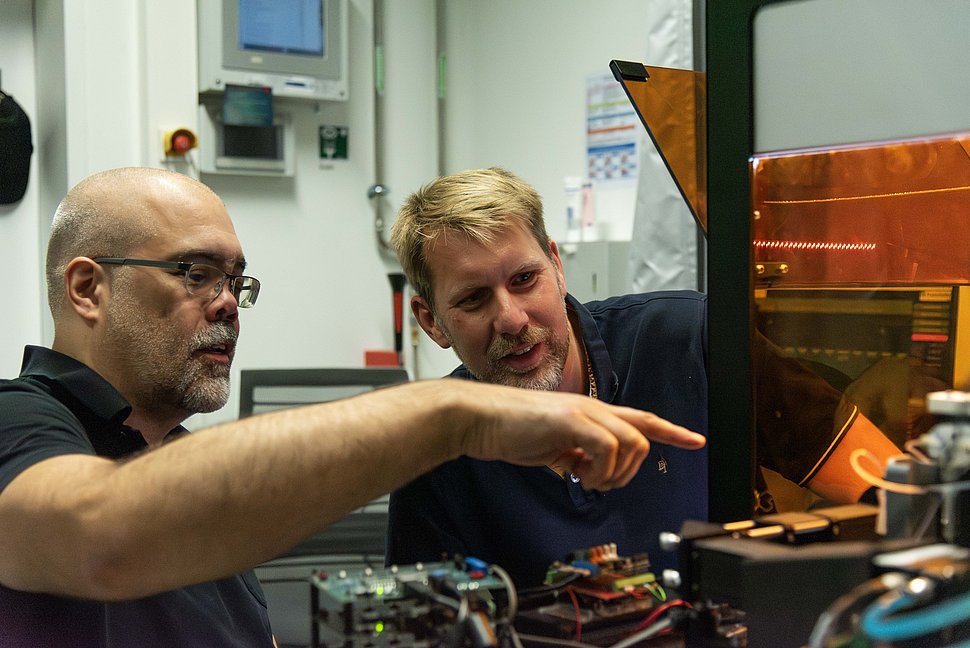

The fully automated measurement of the biophysical properties of hundreds of cell samples in just a few days is the goal of the cooperation project "AutoRAPID," involving scientists from the Max Planck Institute for the Science of Light (MPL) and the Fraunhofer Institute for Production Technology and Automation (IPA) in Mannheim. For the first time, the biophysicists and automation engineers have assembled their individual components into a single setup in Erlangen.

Researchers* from the Department of Biological Optomechanics at MPL, led by Prof. Jochen Guck, have developed a biophysical measurement method which enables them to perform individual mechanical characterization of a large number of cells at a measurement speed of 100 to 1000 cells per second. For example, they can show that the biomechanical properties of pathologically altered cells differ significantly from those of healthy cells. Rapid physical phenotyping in deformational flow, or RAPID for short, is not only the name of the project but also its aim: it involves the maximum acceleration of the measurement speed.

The aim of the AutoRAPID project is to apply the microfluidic measurement method to a fully automated, validated analysis system. Cells flow through a system of channels just a few tens of microns wide to test their deformability. The researchers' long-term goal is to measure the effects of variable parameters, such as drugs, on the physical properties of cells and make this knowledge available for use in therapeutic approaches. The integrated setup has now been assembled for the first time in Erlangen and the interplay between the effects of process automation, from sampling to optical analysis methods, tested.

Prototype for the automation of biophysical cell measurements fully functional

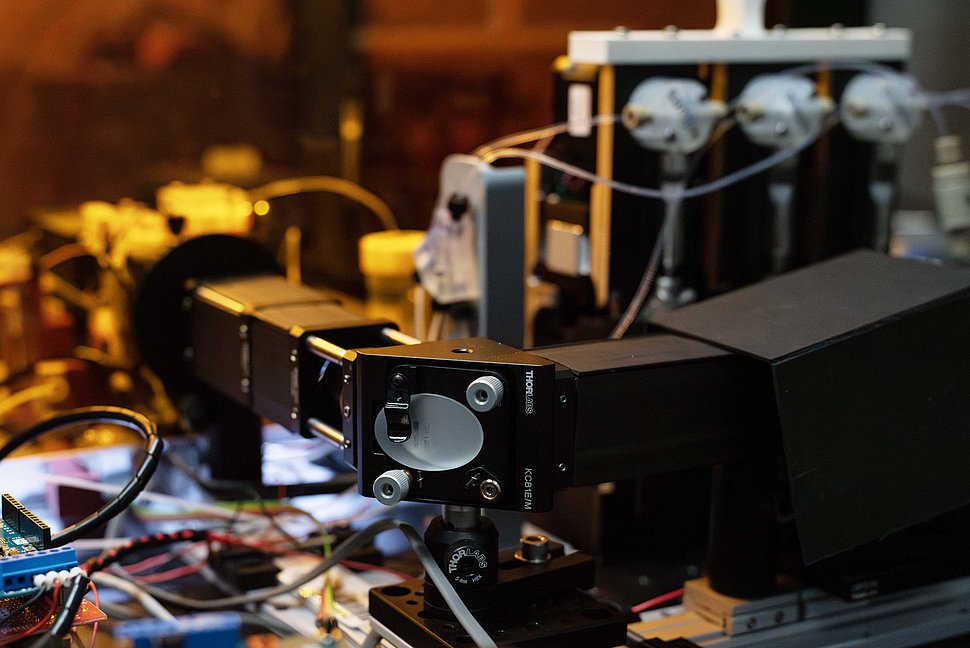

The individual components of the AutoRAPID project were successfully assembled into a system by the two research groups and subjected to a functional test in a joint trial run. The biophysical measurement expertise is provided by the research team of Prof. Jochen Guck, director of the MPL. In the final setup, the specially developed fluidic microchip is combined with optical measurement methods. Using a sophisticated flow system, the scientists are able to analyze the physical properties of the cells and focus on them in various measurements.

The IPA scientists, led by Dr Jens Langejürgen, head of the Clinical Health Technologies department and site manager in Mannheim, are contributing their expertise in process automation. While the conventional manual measurement of a sample requires a time-consuming preparation lasting up to 30 minutes per sample, the new automated AutoRAPID process can analyze up to 96 samples per day. From sample collection and microchip loading by a pipetting robot to control of the three-pump system and the sample analysis itself, all steps of the process can be programmed fully automatically. Another advantage is the newly developed integrated cleaning process of AutoRAPID: the previous disposable chip is replaced by a permanently installed reusable measuring module.

The four-year AutoRAPID project is now in its third (research) year and entering the decisive final project phase. By the end of 2024, the scientists hope to demonstrate a validated measuring device that can automatically perform thousands of measurements. Jochen Guck is confident: "It's great to see a long-planned goal finally becoming tangible. Soon we will be able to perform series of measurements that were unthinkable just a short time ago. The next step is to test the automatic analysis procedure in practice and put it through its paces in daily use." Jens Langejürgen is pleased: "Thanks to the excellent cooperation in this project, we were able to quickly establish a sufficiently automated measurement setup for the extensive practical test phase in Erlangen. At the same time, we have an identical copy of the system in Mannheim, which enables us to carry out further optimisation steps in parallel. In the joint interdisciplinary project team, we benefit from the very different experiences and approaches."