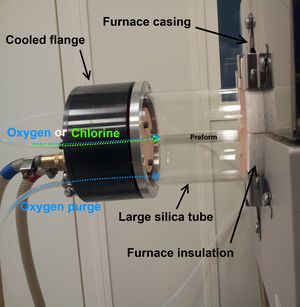

Chlorine treatment to reduce contaminants

The step-index preforms used for conventional optical fibres can be drawn directly to fibre without exposing the core to the atmosphere, so that contamination from, for example, water does not occur. In the case of PCF, however, the stacking procedure involves exposure to the atmosphere, which introduces contaminants. We have explored reducing contamination by treating the primary and/or secondary preform with chlorine and/or oxygen gas while heating it to 900°C. When treated with chlorine gas, the preforms produced fibres with a clear reduction in the water-related absorption peak at 1380 nm (the first vibrational overtone of the OH-bond). We also investigated the influence of the dryness of the gas used for pressurising the air-hole microstructure during fibre drawing. We found that reducing the water content of the gas from <2 ppm to <0.5 ppm approximately halved the absorption loss at 1380 nm, even when the preforms were not treated with chlorine before fibre drawing [Frosz (2016)].