Soft-glass Photonic Crystal Fibers

Soft-Glass Photonic Crystal Fibers

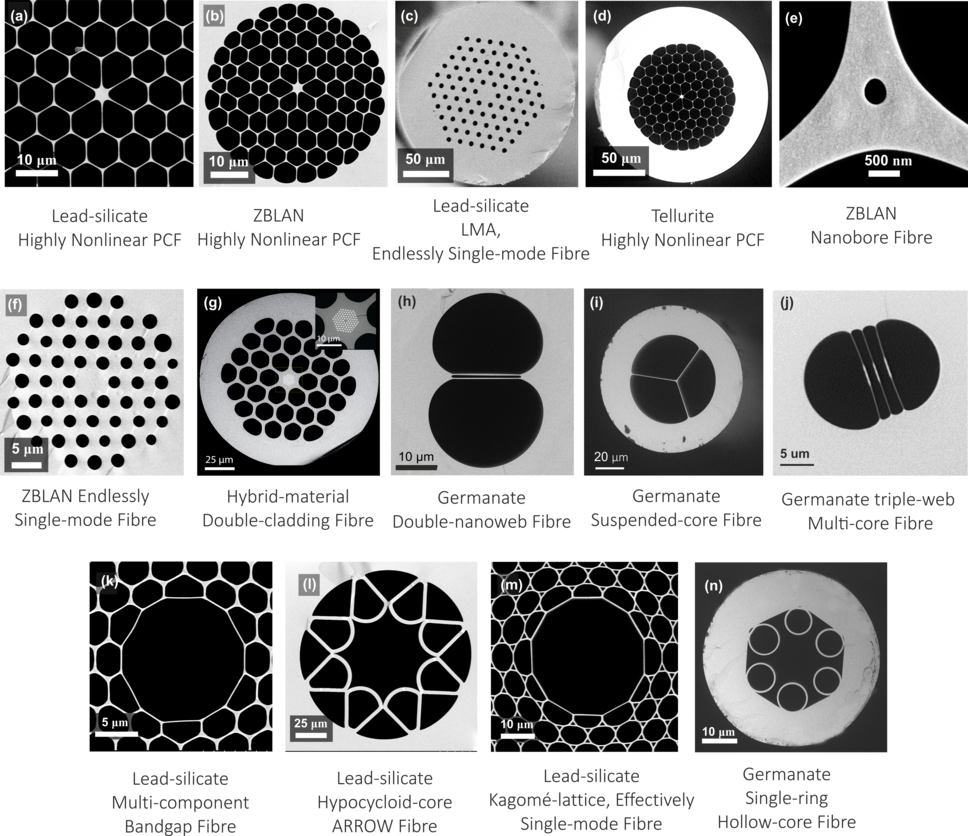

Photonic crystal fibers (PCFs) and microstructured optical fibers (MOFs) made from soft glasses (e.g., heavy-metal oxide, fluoride or chalcogenide) have attracted much interest because of extended ultraviolet (UV) and mid-infrared (mid-IR) transmission windows, higher Kerr nonlinearities and refractive indices and increased rare-earth solubility. Although such fibers hold much promise as novel waveguides, with applications in for example sensing and supercontinuum generation from ultraviolet to mid-infrared, fabricating them remains, however, significantly challenging due to much faster changes in viscosity with temperature as well as glass devitrification during the repeated reheating steps required by the “stack-and-draw” method, which is the most highly developed fabrication technique for such fibers, providing great flexibility for drawing both solid and hollow-core fibers, not only from fused silica, but also from many soft glasses. Not all nanostructures can be drawn from stacked preforms, however, examples being multiple glass nano-membranes or nano-spikes. Moreover, when working with soft glasses, many of which are thermally instable, it is important to minimise the number and duration of re-heating steps so as to avoid the risk of glass crystallisation.

Advanced fiber drawing techniques have been developed over the last few years, examples being 3D printing of complex extrusion dies, advanced differential etching procedures, techniques for producing chirally twisted fibers, polymer/glass hybrid sturcutres. These new techniques enable us bring novel soft-glass fiber structures for a range of different applications, such as opto-mechanical devices, imaging through multimode fibers, photochemistry and nonlinear wavelength conversion.