Etching basic information

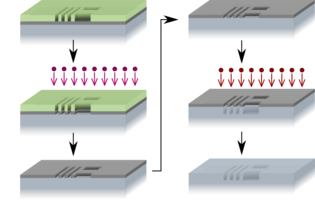

Dry etching is a widely used technique in micro and nanofabrication to transfer lithographically patterned structures in underlying materials. The TDSU 1 runs several reactive ion etching systems to solve the different structuring issues. These systems combine physical and chemical etching mechanisms to achieve fast processes, which leads to structures with steep anisotropic profiles and a very high resolution.

One of the inductive coupled plasma etching systems (ICP-RIE) is used as a multi-purpose system for the anisotropic etching of silicon based materials, oxides, glasses, metals and III-V semiconductors. The other ICP-RIE system is dedicated mainly to deep etching of glass and fused silica.

With the cryogenic system we have the possibility to perform high aspect ratio etching of silicon using temperatures down to -130°C, which is characterized by very smooth sidewalls. For very deep silicon etching (> 100 µm) the MFCs, which are directly positioned at the chamber, also support the usage of standard Bosch processes at room temperature.