Lithographie basic information

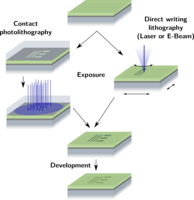

Lithography is typically used to expose the desired pattern. The resist material, which is sensitive to used radiation, is coated ontop of the sample and afterwards exposed to the radiation. After a development step the desired pattern exists as a resist structure which then can be processed further.

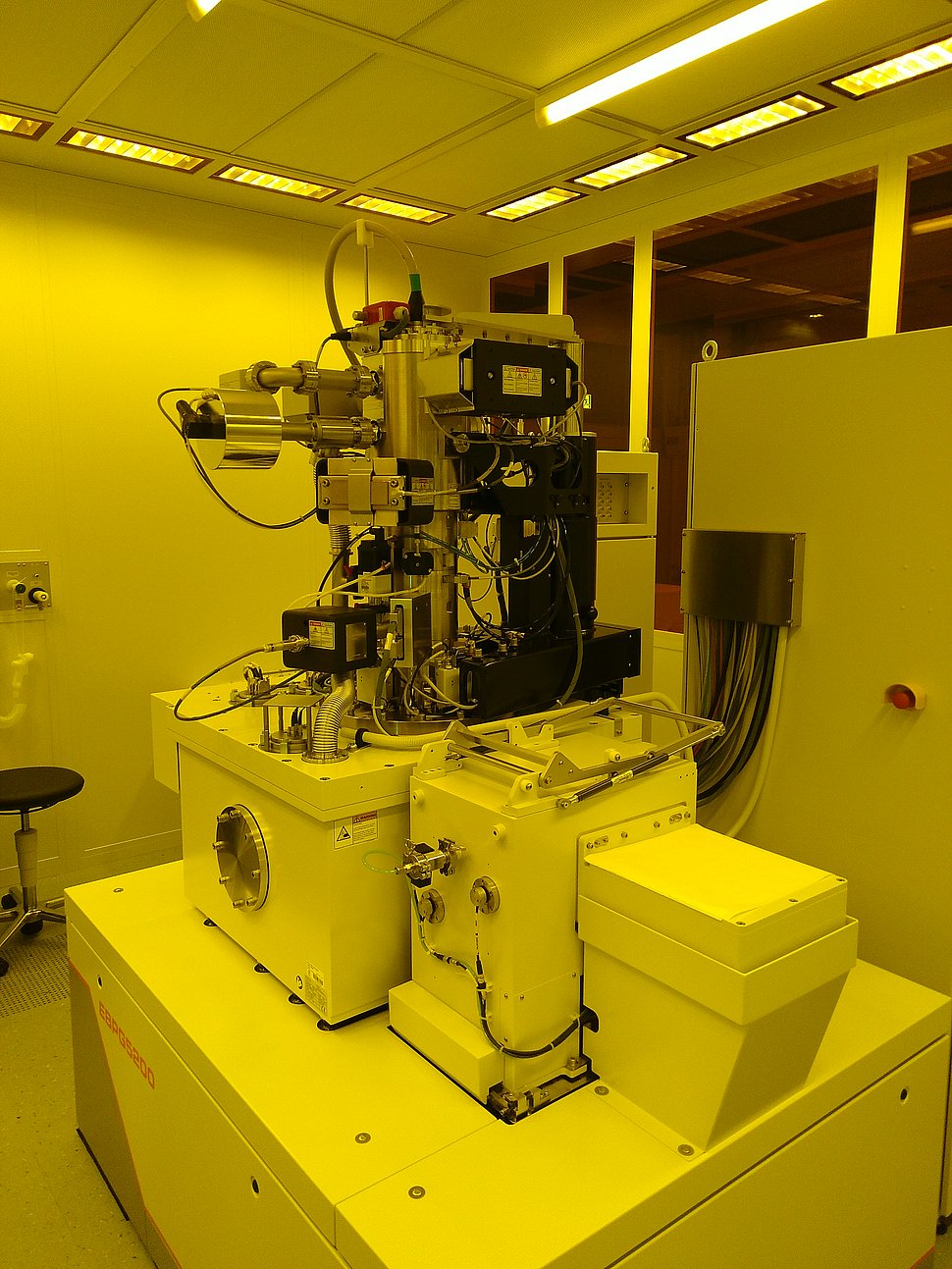

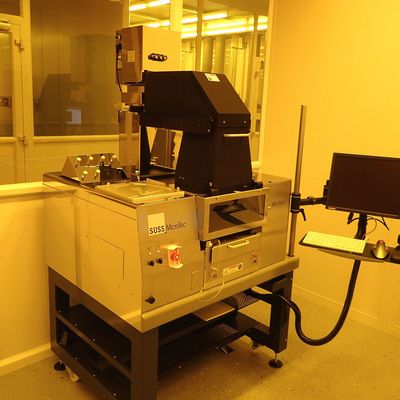

The TDSU 1 offers different possibilities for the lithography step based on electrons or photons for exposure. There are two direct writing systems available (Electron beam based Raith 150two and laser based DWL 66+) and a mask aligner MA6Gen4 for contact and proximity lithography.